PRODUCT DESCRIPTION

Carbon Fiber Honeycomb Sandwich Panel: A High-Performance Structural Material Carbon fiber honeycomb sandwich panel is a cutting-edge composite structure celebrated for its exceptional strength-to-weight ratio, making it a game-changer in industries demanding both lightness and durability. Composed of three core layers—high-strength carbon fiber face sheets bonded to a lightweight honeycomb core (typically made of aluminum, aramid, or thermoplastics)—it merges the rigidity of carbon fiber with the weight-saving efficiency of the honeycomb design.

This panel excels in withstanding bending, compression, and impact while remaining significantly lighter than traditional materials like steel or aluminum alloys. It boasts excellent corrosion resistance, thermal stability, and dimensional consistency, performing reliably in harsh environments—from aerospace (e.g., aircraft interiors, satellite structures) and automotive (high-performance vehicle bodies) to marine (boat hulls) and construction (architectural facades). Moreover, its customizable thickness, size, and core material options allow tailored solutions for specific needs, such as enhancing insulation or optimizing load-bearing capacity. As industries shift toward energy efficiency and lightweighting, carbon fiber honeycomb sandwich panels continue to replace conventional materials, driving innovation in high-tech and heavy-duty applications worldwide.

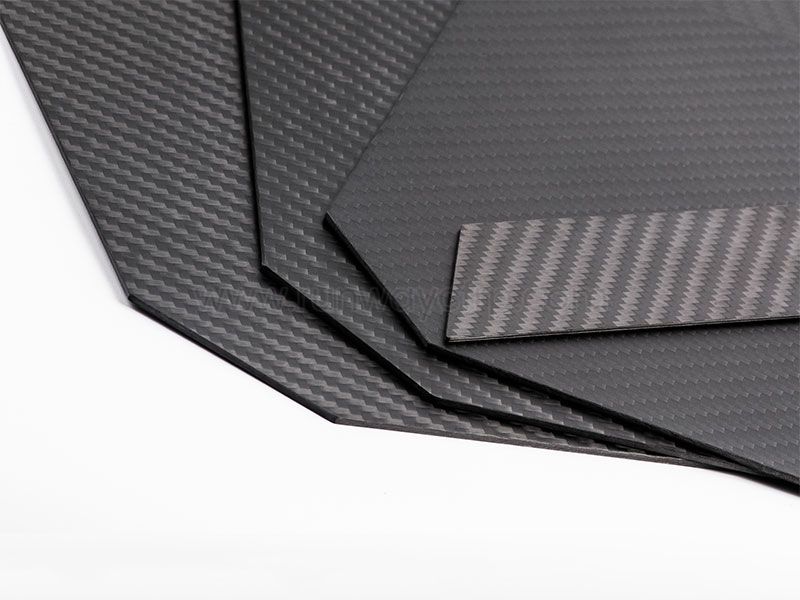

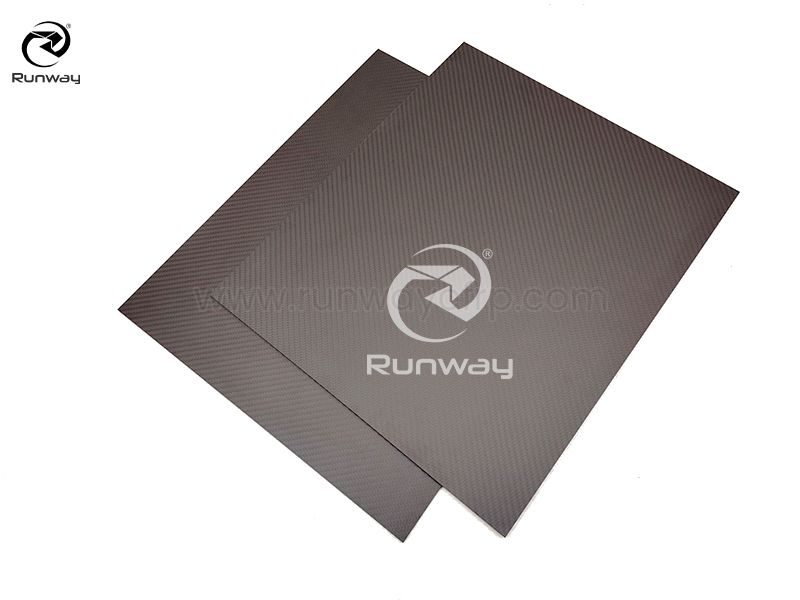

3K Carbon Fiber Epoxy Resin Sheet

Designed to meet the most exacting standards of any carbon fibre sheet, our 3K carbon fiber epoxy resin sheet is manufactured from 100% carbon fibre reinforcement and pressed at high temperature and pressure to create a high performance double sided carbon fibre sheet with a smooth, high-gloss finish on both sides.

+86 13275331467

Science & Technology Industrial Park, Zhangdian, Zibo, Shangdong, China